Lake Asphalt of Trinidad & Tobago (1978) Limited has emerged as a true pioneer in the region with the supply and manufacture of Cationic Bitumen Emulsions which complement its product range. This pioneering feat is made possible with the acquisition of a state of the art SEP Continuous Inline 12 metric ton per hour plant, backed by the technology of a world leader in business, Akzo Nobel.

The plant is fully automated producing materials of superior quality and high performance. The engineering and production staff are experienced and well trained, having received extensive overseas training on the operations of the plant and manufacture of the emulsified bituminous products. As outlined in our product slate the plant has the capacity to manufacture a wide range of Bitumen Emulsions which are used for road surfacing and maintenance, among other purposes. This venture is a tangible sign of our commitment towards providing premier quality surfacing materials to our ever expanding cadre of customers globally.

CATIONIC BITUMEN EMULSIONS

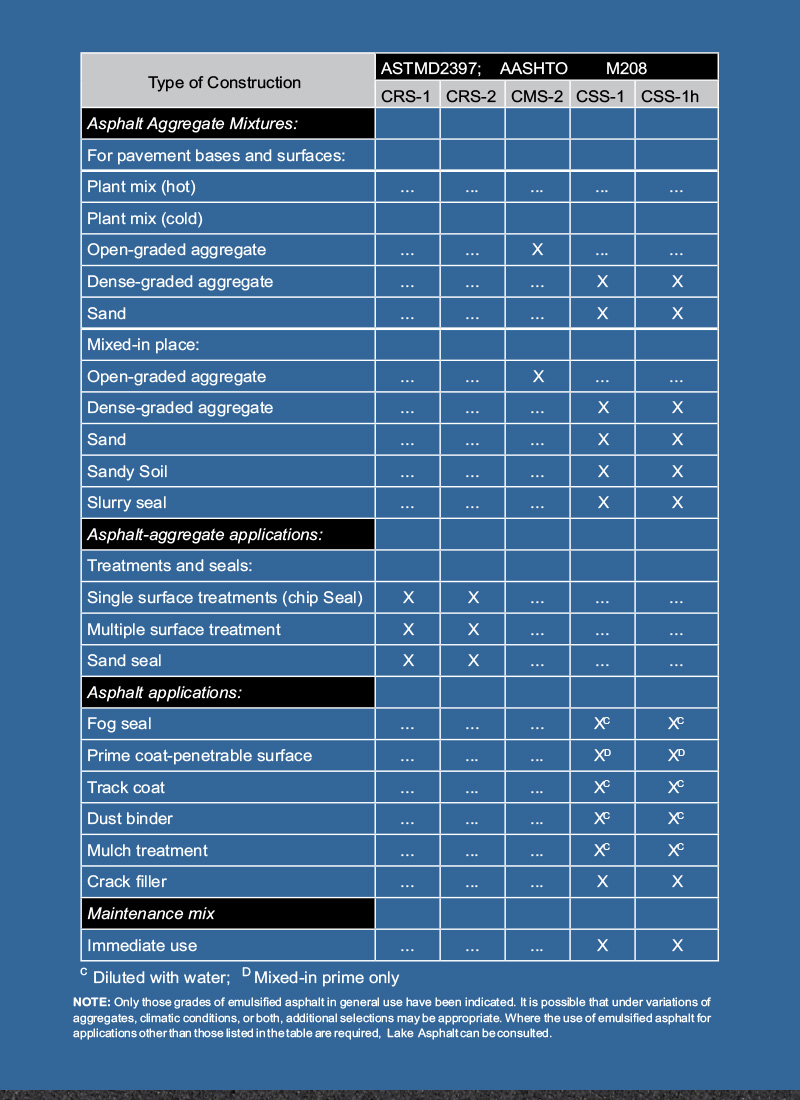

The rapid setting grades are designed to react quickly with aggregate and revert from the emulsion state to asphalt. They are used primarily for spray applications such as aggregate (chip) seals, sand seals, surface treatments and asphalt penetration macadam. CRS-2 grades have a higher viscosity to minimize potential for runoff.

The medium setting grades are designed for mixing with coarse aggregate, as these grades do not break immediately upon contact with aggregate. CMS mixes possess some measure of workability and have high viscosities to prevent runoff. These are generally used for cold mix applications and mixed-in-place operations.

The slow setting grades are designed for maximum mixing stability. They are used with high fines content and densegraded aggregates. All slow setting grades have low viscosities that can be further reduced by adding water. It can then be used for tack coats, prime coats, fog seals and dust palliative. CSS-1h has a stiffer/harder emulsion residue. Lake Asphalt produces Cationic Bitumen Emulsions according to American Society for Testing and Materials (ASTM) Cationic Emulsified Asphalt specifications ASTM D2397.

Specific Emulsions to suit your aggregate type and job requirements Lake Asphalt produces Cationic Bitumen Emulsions in a state of the art continuous plant with a capacity of twelve (12) metric tons per hour, backed by technology of a world leader in the business, Akzo Nobel.

TLOG, Trinidad Lake Asphalt Oil and Gas Limited was registered in Trinidad and Tobago in 2009 in accordance with the companies act 1995 to operate as a business entity in the Hydrocarbon Sector including, upstream, downstream and midstream activities.